Building Management System

Building Automation

Our Building Automation Division under takes Engineering

Building Automation

Our Building Automation Division under takes Engineering

Understanding Building Automation and Control Systems

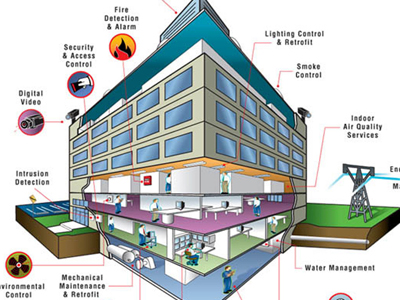

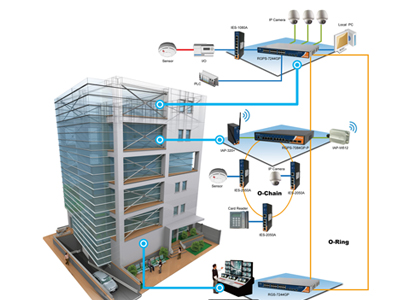

Building Automation Systems (BAS) are centralized, interlinked, networks of hardware and software, which monitor and control the environment in commercial, industrial, and institutional facilities. While managing various building systems, the automation system ensures the operational performance of the facility as well as the comfort and safety of building occupants. Typically, such control systems are installed in new buildings or as part of a renovation where they replace an outdated control system.

Our Building Automation Division under takes Engineering, Supply, Installation (case to case basis), Testing, Commissioning, Handing over to the client and Maintenance service to the End user.

Related Terms

- Building Automation and Control Systems (BACS), Building Control System (BCS), and/or Building Management System (BMS)—same as "Building Automation System" or the subject of this page.

- Controls—This term is appropriate in describing discrete devices that control particular pieces of equipment or processes..

- Direct Digital Control (DDC)—describes the communication method used in modern devices (hardware and software). Collectively, DDC products control various building systems and form the automation system.

- Energy Management System (EMS)—generally understood to be the same as a "Building Automation System" but may have special emphasis on energy metering/monitoring

- Energy Management and Control System—well, you're getting the idea.

- Smart (Intelligent) Building—a building equipped with a data-rich BAS.

Generally, building automation begins with control of mechanical, electrical, and plumbing (MEP) systems. For instance, the heating, ventilation, and air-conditioning (HVAC) system is almost always controlled, including control of its various pieces of equipment such as:

- Chillers

- Boilers

- Air Handling Units (AHUs)

- Roof-top Units (RTUs)

- Fan Coil Units (FCUs)

Early control systems were pneumatic or air-based and were generally restricted to controlling various aspects of the HVAC system. Common pneumatic devices include controllers, sensors, actuators, valves, positioners, and regulators. Due to their large base of installation throughout the 1960s and 1970s, pneumatic control systems are still in place in a majority of existing buildings, especially in established metropolitan areas.

Analog electronic control devices became popular throughout the 1980s. They provided faster response and higher precision than pneumatics. However, it was not until digital control or DDC devices came on the scene in the 1990s that a true automation system was possible. However, as there were no established standards for this digital communication, various manufacturers, created their own (proprietary) communication methods.

The automation system was fully functional but was not "interoperable" or capable of mixing products from various manufacturers. Thus, a given building or portfolio could be "locked" into a specific manufacturer. This is not necessarily a problem unless the relationship with the associated service provider is challenging. By the late 1990s and especially into the 2000s, movements were afoot to standardize on "open" communication systems. The American Society of Heating, Refrigerating and Air-conditioning Engineers (ASHRAE) developed the BACnet communication protocol that eventually became the industry open standard.

A properly trained in-house staff can manage the operation and, sometimes, the maintenance of the BAS. However, system design and initial installation is almost always accomplished by controls professionals such as dedicated controls contractors or system integrators. In practice, the controls contractor is a sub-contractor to the mechanical contractor. Sometimes, the mechanical contractor will have a dedicated controls division. Electrical contractors with controls teams are also common and multi-functional system integrators are becoming more common for today's complex facilities.

These controls professionals can provide on-going service or train your in-house staff to self-perform service. The automation system can also offer you an incredible amount of data related to building performance, and with this data in hand, you can make more intelligent decisions. And, if you are building green, be aware that an automation system can contribute greatly to your ability to earn such recognition as the EPA ENERGY STAR or the LEED certification associated with the U.S. Green Building Council (USGBC).